Choosing the right silicone for moulds may seem trivial, but it’s actually one of the most important aspects to ensure your mould is both functional and durable.

Whether you're a beginner or more experienced, understanding silicone hardness is essential for precise results and a smooth working process.

Hardness determines the flexibility of the mould, its ability to reproduce fine detail, and how easy it is to demould.

And then there’s a frequently overlooked question: should you use translucent or opaque silicone?

Let’s break it down with real-life examples.

🔎 What Is Shore Hardness?

Silicone is classified using the Shore A scale, which measures how soft or firm it is once cured.

This scale is crucial for choosing the right type of silicone for resin casting, jewellery, or other materials.

-

The lower the number, the more flexible the silicone.

-

The higher the number, the stiffer it is.

Choosing the right Shore hardness helps you make moulds that are both durable and easy to demould.

🧭 Quick Guide by Shore Hardness

🔹 Shore A 10–15

Very soft silicone – ideal for dried flowers, jewellery, or small items.

✔️ Great for capturing complex textures and safe demoulding without breakage.

🔹 Shore A 20–25

Still flexible, but more stable.

✔️ Suitable for coasters, decorative shapes, or moderately complex moulds.

🔹 Shore A 30–40

Rigid silicone – ideal for large or flat moulds.

✔️ Perfect for lamp bases, trays, or items used frequently.

Pure Mold 10 - Silicone for Crafting and Fine Details

Pure Mold 20 - Universal Silicone for Sculptures and Artistic Objects

Pure Mold 30 – Ideal Silicone for Moulds in Cement, Plaster, Mortar, and Decorative Stones

How Does Hardness Affect Demoulding?

One of the most common mistakes is underestimating how much silicone hardness impacts the demoulding phase.

If the silicone is too rigid for detailed items, you risk damaging both the mould and the cast piece.

👉 For intricate projects: opt for Shore A 10–15.

Better to Use Translucent or Opaque Silicone?

It depends on your needs:

-

Translucent: useful for spotting air bubbles and monitoring the internal process.

-

Opaque: more resistant, with faster curing. Ideal for simple and sturdy moulds.

Understanding this distinction helps you choose based on your working style.

Practical Examples

-

Want to replicate dried leaves? → Use Shore A 10–15 translucent: perfect for maximum visible detail.

-

Moulds with bold textures (bark, reliefs)? → Try Shore A 20–25, still flexible but more stable.

-

Need to quickly cast decorative items? → Go for a soft translucent silicone, easy to work with.

🧠 Think About These 3 Key Factors:

Detail – how precise the replica must be

Size – large pieces need more structural stability

Frequency of use – durable silicone is a better long-term investment

These will guide you in choosing the perfect silicone for your project.

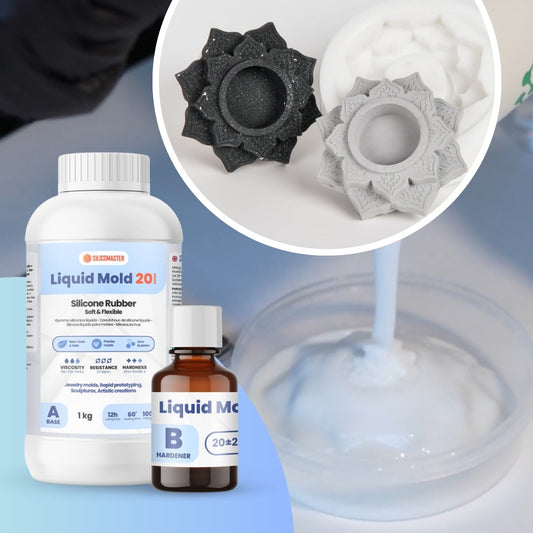

Liquid Mold 5 - Silicone for Ultra-Soft Moulds and Fine Details

Liquid Mold 30 - Silicone for Resilient Moulds and Heavy Materials

Liquid Mold 40 - Silicone for Industrial and Durable Moulds

In Summary

Choosing the right silicone is not just a technical decision — it's part of the creative process.

Understanding Shore hardness, flexibility, visibility, and demoulding behaviour will help you achieve clean, professional, and satisfying results.

Remember:

➕ More detail → Use soft, translucent silicone

➕ Larger pieces / frequent use → Opt for rigid silicone

➕ Need to see inside → Choose translucent

➕ Want speed and strength → Go for opaque