Using SILICOMASTER by ResinPro® silicones requires a few precautions to achieve professional, high-quality results. In this section, we explore practical techniques and tips to maximise the effectiveness of SILICOMASTER by ResinPro® products across various contexts, including crafts, construction, and the film industry.

1. Crafts and Modelling

Mould Preparation:

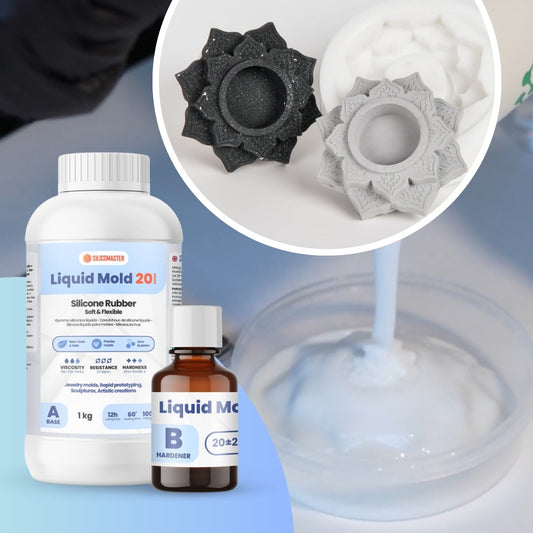

Use Liquid Mold (Tin-Cured) Shore 7–20 or Pure Mold (Platinum-Cured) Shore 10–20 for craft projects like jewellery and miniatures. Shore hardness A 7–10 or 20 and suitable viscosity are ideal for fine details.

Tip: Before pouring the silicone, apply a release spray to ease demoulding and preserve intricate details.

Casting and Demoulding:

Pour silicone slowly to avoid air bubbles. Once cured, carefully remove the object to avoid damage.

Pro tip: For especially complex objects, brush them the day before with the same silicone used for the mould.

2. Construction and Prototyping

Making Moulds for Cement and Heavy Materials:

For large and durable moulds, opt for Shore A 30–40 silicones like Liquid Mold or Pure Mold. These silicones are designed to withstand the weight and pressure of cement and other heavy materials.

Practical tip: Coat the base of the mould with a release agent to ensure easy demoulding and extend the mould’s lifespan.

Prototyping and Precision:

For models requiring precision, Platinum-Cured Pure Mold is the ideal choice. Its low shrinkage and chemical resistance make it perfect for detailed prototypes and mechanical parts.

Tip: For maximum mould precision, use a vacuum degasser to remove air bubbles before curing.

3. Cinema and Special Effects

Creating Prosthetics and Flexible Props:

SILICOMASTER by ResinPro® Shore A 7–10 (Liquid Mold Shore A 7 and Pure Mold Shore A 10) is perfect for special effects and prosthetics. Thanks to its softness and flexibility, it fits the body well and allows natural movement.

Usage tips: Use sculpting tools to add wrinkles and textures for realistic effects.

Moulds for Masks and Decorative Props:

Platinum-Cured Pure Mold is excellent for detailed, durable scenic items. The silicone's durability ensures repeated use without losing elasticity.

Pro tip: Add colour pigments for realism and apply anti-shine powder to avoid light reflections on set.

4. Food and Cosmetic Use

Moulds for Sweets and Solid Cosmetics:

Silfood, certified for food contact, is ideal for moulds used in sweets, chocolate, and soap production. This silicone is safe for contact with food and solid cosmetics, and it’s easy to clean.

Safety guide: Ensure the silicone is fully cured before use. Avoid contact with non-food substances during preparation to maintain hygiene.

Tips for Food Mould Creation:

Pour slowly to avoid air bubbles and achieve a smooth result. Apply a release spray for easy demoulding.

Tip: For desserts with intricate details, lightly lubricate the mould to extract the finished product without damage.

5. Troubleshooting Common Issues

Air Bubbles: These often occur during pouring. To eliminate them, pour slowly and, if possible, use a vacuum chamber to degas the silicone before curing.

Mould Deformation: To avoid deformation, ensure the surface where silicone is poured is flat and stable.

Premature Wear: If the silicone wears too quickly, switch to a platinum-based silicone like Pure Mold, which provides greater resistance to repeated use.

© All rights reserved. Reproduction, distribution or unauthorised use of the content on this site is prohibited without the written consent of the copyright holder.

RESINPRO SASU, n° 4 Allée du Marais de Condé, Rochy-Condé, 60510, France

VAT FR05842797722, SIRET 842 797 722 00019