Each SILICOMASTER silicone by ResinPro® is designed to meet specific technical needs. Understanding the fundamental parameters of silicones helps optimise results and ensures safe and professional use. In this section, we explore the main technical parameters of SILICOMASTER silicones by ResinPro® and provide guidelines for interpreting and using them effectively.

Density

The density of a silicone is crucial for the stability and rigidity of the material. SILICOMASTER silicones by ResinPro® vary in density depending on Shore hardness, with lower hardness products tending to be less dense and more flexible.

Optimal Density for Detailed Projects: For objects requiring precision and fine detail, such as jewellery and miniatures, it is advisable to use silicones with higher density.

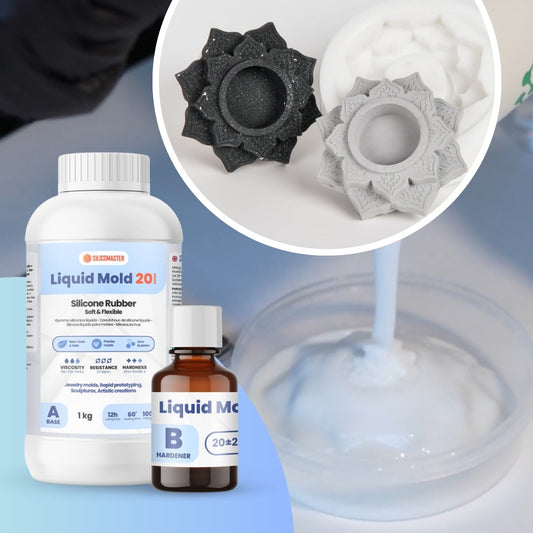

SILICOMASTER by ResinPro® Lines: Tin-cured silicones – Liquid Mold and Platinum-cured silicones – Pure Mold are available in different densities to meet flexibility and hardness requirements.

Viscosity

Viscosity measures the fluidity of the liquid silicone and affects the material’s ability to cover details and infiltrate mould cavities.

High Viscosity: Indicates a slower flow, ideal for large moulds with fewer details.

Low Viscosity: Promotes penetration into fine details and reduces the risk of air bubbles, making it ideal for precision projects such as sculptures and prototyping.

SILICOMASTER by ResinPro® Tip: Low-viscosity silicones are perfect for creating complex objects, such as miniatures and detailed decorative components.

Pot Life (Curing Time)

Pot life is the time required for silicone to transition from liquid to solid. Knowing the pot life is crucial for planning the work and ensuring that the material is fully stabilised before use.

Fast Pot Life: Suitable for quick production projects but requires some skill to avoid mistakes during casting.

Slow Pot Life: Recommended for large projects or for those who want to work more calmly, allowing better material distribution.

SILICOMASTER by ResinPro® Advice: Tin-cured silicones – Liquid Mold have a fast pot life, useful for quick projects. Platinum-cured silicones – Pure Mold, on the other hand, offer slightly longer curing times, allowing greater control.

Heat Release During Curing

During curing, some silicones generate minimal heat, which can still affect the stability of the mould or the object being made.

Effects of Heat Release: Heat release can cause deformations in sensitive materials or thin objects. For applications requiring low thermal release, platinum-based silicones are recommended.

SILICOMASTER by ResinPro® Tips: For delicate projects or thin objects, Pure Mold offers stable curing with minimal heat release.

Resistance to Chemical and Mechanical Agents

The chemical and mechanical resistance of silicone is essential for projects exposed to extreme conditions, such as contact with chemicals, moisture, or heat.

Chemically Resistant Silicones: Platinum-based silicones such as Pure Mold are resistant to many chemical agents and suitable for long-term use or exposed environments.

Mechanical Resistance: For moulds used frequently or under pressure, mechanical resistance is crucial. SILICOMASTER silicones by ResinPro® are designed to withstand repeated pressure, ensuring long-lasting results.

Technical Comparison Tables

Below is a summary of the main technical characteristics of SILICOMASTER by ResinPro® silicones.

Technical Parameters of Tin-Cured Silicone (Liquid Mold)

| Test | Liquid Mold 7 | Liquid Mold 15 | Liquid Mold 20 | Liquid Mold 25 | Liquid Mold 30 | Liquid Mold 40 |

|---|---|---|---|---|---|---|

| Colour (Part A) | White | – | – | White | – | – |

| Colour (Part B) | Transparent to light yellow | – | – | Transparent to light yellow | – | – |

| Density (g/cm³) | 1.15 | 1.18 | – | 1.20 | 1.20 | 1.20 |

| Catalyst (Part B) | Tin-based catalyst | – | – | Tin-based catalyst | – | – |

| Viscosity at 25°C (mPa.s) Part A | 12000 ± 2000 | 18000 ± 2000 | 26000 | 22000 ± 2000 | 23000 ± 2000 | 24000 ± 2000 |

| Viscosity at 25°C (mPa.s) Part B | 200–300 | 200–300 | – | 200–300 | 200–300 | 200–300 |

| Mixing Ratio (A:B) | 100:3 | 100:3 | 100:2 | 100:3 | 100:3 | 100:3 |

| Working Time at 25°C (min) | 50–60 | 50–60 | 60–80 | 50–60 | 30–40 | 30–40 |

| Curing Time at 25°C (hours) | 10–12 | 10–12 | 24 | 10–12 | 8–10 | 8–10 |

| Hardness (Shore A) | 5 ± 2 | 15 ± 2 | 20 ± 2 | 25 ± 2 | 30 ± 2 | 38 ± 2 |

| Tear Resistance (kN/m) | 8 | 16 | 27 | 25 | 25 | 19 |

| Tensile Strength (MPa) | 1.5 | 2.2 | 4.3 | 2.5 | 3.5 | 4 |

| Elongation (%) | 500 | 450 | 490 | 400 | 350 | 300 |

Technical Parameters of Platinum-Cured Silicone (Pure Mold)

| Test | Pure Mold 10 | Pure Mold 20 | Pure Mold 30 | Pure Mold 35HR | SilFood 9300-30 |

|---|---|---|---|---|---|

| Colour (Part A) | Translucent | Translucent | Translucent | Translucent | Transparent |

| Colour (Part B) | Translucent | Translucent | Translucent | Translucent | Clear |

| Density (g/cm³) | 1.08 | 1.08 | 1.10 | 1.10 | 1.10 |

| Catalyst (Part A) | Platinum-based catalyst | – | – | Platinum-based catalyst | – |

| Viscosity at 25°C (mPa.s) Part A | 5000 ± 1000 | 9000 ± 1000 | 13500 ± 1000 | 13500 ± 1000 | 85000 ± 2000 |

| Viscosity at 25°C (mPa.s) Part B | 4500 ± 1000 | 8000 ± 1000 | 12500 ± 1000 | 12500 ± 1000 | 100–200 |

| Mixing Ratio (A:B) | 1:1 | 1:1 | 1:1 | 1:1 | 10:1 |

| Working Time at 25°C (min) | 30–40 | 30–40 | 30–40 | 30–40 | 40–50 |

| Curing Time at 25°C (hours) | 3–5 | 3–5 | 4–6 | 4–6 | 7–9 |

| Hardness (Shore A) | 10 ± 2 | 20 ± 2 | 30 ± 2 | 30 ± 2 | 30 ± 2 |

| Tear Resistance (kN/m) | 14 | 15 | 16 | 16 | 14 |

| Tensile Strength (MPa) | 3.2 | 4.0 | 4.2 | 4.2 | 3.5 |

| Elongation (%) | 450 | 420 | 400 | 400 | 350 |

Comparison Table: Main Properties

| Parameter | Tin-Cured – Liquid Mold | Platinum-Cured – Pure Mold | SilFood |

|---|---|---|---|

| Density | Medium | Variable (high precision) | High |

| Viscosity | High (great detail) | Low (easy infiltration) | Medium |

| Curing Time | Fast | Moderate | Moderate |

| Heat Release | Moderate | Low | Low |

| Chemical Resistance | Moderate | High | High |

| Mechanical Resistance | Medium | High | High |

©All rights reserved. The reproduction, distribution or unauthorised use of the contents on this site is prohibited without the written consent of the copyright holder.

RESINPRO SASU, No. 4 Allée du Marais de Condé, Rochy-Condé, 60510, France VAT FR05842797722, SIRET 842 797 722 00019