SILICOMASTER silicone rubbers by ResinPro® are extremely versatile materials, known for their durability, elasticity, and ability to replicate intricate details. In this chapter, we explore the various types of SILICOMASTER silicone rubbers for moulds to help you select the most suitable product for your needs.

Composition, Properties and Advantages of Silicone Rubbers

Silicone rubbers are mainly composed of silicon and oxygen chains, which provide resistance to extreme temperatures (up to +250 °C), oxidation, and moisture. SILICOMASTER silicone rubber by ResinPro® is available in two RTV (Room Temperature Vulcanising) two-part formulations that cure at room temperature:

-

Pure Mold (addition-cure): A platinum-cured RTV silicone with a 1:1 mixing ratio, designed for high precision and non-toxicity, with virtually zero shrinkage (<0.05%).

-

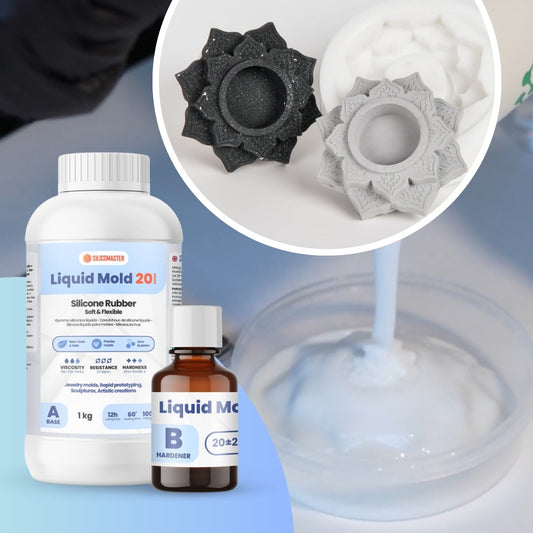

Liquid Mold (condensation-cure): A tin-cured RTV silicone with a 100:5 mixing ratio, offering a cost-effective and versatile option for artistic and restoration projects.

Main Uses of SILICOMASTER Silicone Rubbers by ResinPro®

SILICOMASTER silicone rubbers are ideal for creating elastic, durable, and resistant moulds that can reproduce identical copies of existing models. The resulting casts can be used to make objects from materials such as:

-

Plaster

-

Cement

-

Resins (epoxy and polyurethane)

-

Wax

-

Soap

-

Low-melting metal alloys such as tin

-

Food materials (with certified food-grade silicone)

Classification of Silicone Rubbers for Moulds

Pure Mold Rubbers (Addition-Cure):

-

Characteristics: Platinum-cured Pure Mold ensures excellent dimensional stability and longevity. With its near-zero shrinkage, it’s perfect for high-precision projects.

-

Catalysts: The platinum catalyst formula offers a 1:1 mixing ratio and demoulding times from 1 to 6 hours depending on temperature.

-

Applications: Ideal for complex and long-term projects requiring high accuracy and durability.

Liquid Mold Rubbers (Condensation-Cure):

-

Characteristics: Tin-cured Liquid Mold offers an affordable solution for artistic and restoration projects. It has a linear shrinkage of about 1.5%, yet offers high tear resistance and accurate detail reproduction.

-

Catalysts: With a 100:5 mixing ratio, Liquid Mold allows demoulding in 2 to 12 hours depending on the reactivity of the catalyst.

-

Applications: Perfect for artistic work, bas-reliefs, and moulds not intended for intensive or long-term use.

Special Silicones for Food and Anatomical Use

Some platinum-based Pure Mold formulations are non-toxic and safe for contact with food and solid cosmetics. These certified variants are also used for anatomical casts and prosthetics in the film industry.

Available Formats: Paste and Liquid Rubbers

SILICOMASTER RTV-2 silicones by ResinPro® are available in both liquid (e.g. Pure Mold, Liquid Mold) and paste versions (“iGum”). Liquid rubbers can be poured directly onto the model, while mouldable pastes are ideal for vertical surfaces and manual impressions.

Guidelines for Choosing the Right Silicone Rubber

To choose the most suitable SILICOMASTER rubber, consider:

-

Size and complexity: Small, detailed models require soft, flexible rubbers; larger models benefit from harder rubbers.

-

Curing time: Select based on your time requirements – ambient temperature can affect curing speed.

-

Shrinkage: Pure Mold is ideal for precision work due to minimal shrinkage; Liquid Mold (1.5% shrinkage) is suitable when exact dimensions are not critical.

Advantages of Silicone Rubber Moulds

Compared to rigid moulds, SILICOMASTER silicones by ResinPro® offer:

-

Cost-effectiveness: Lower equipment costs.

-

Ease of use: Low-viscosity rubbers help prevent air bubbles.

-

Easy demoulding: High elasticity allows for simple removal.

-

Precise replication: Accurately reproduces fine details without the need for release agents.

© All rights reserved. Reproduction, distribution, or unauthorised use of this content is prohibited without written consent from the copyright holder.

RESINPRO SASU, 4 Allée du Marais de Condé, Rochy-Condé, 60510, France

VAT FR05842797722 – SIRET 842 797 722 00019