Choosing between platinum-cured and tin-cured silicones is crucial for achieving the best results based on your specific project. SILICOMASTER by ResinPro® offers both types, each with unique characteristics that influence durability, precision, and ease of use. Below is an analysis of the key differences to help you select the most suitable product.

1. Durability and Wear Resistance

Platinum-Cured Silicone – Pure Mold

Platinum-based silicones from SILICOMASTER by ResinPro®, such as Pure Mold, offer superior durability and excellent wear resistance. They are ideal for projects that require frequent and long-term use, such as moulds for decorations and artistic items.

Examples of use: Moulds that need to be reused many times and must retain their shape over time, such as interior decorations or advanced prototyping projects.

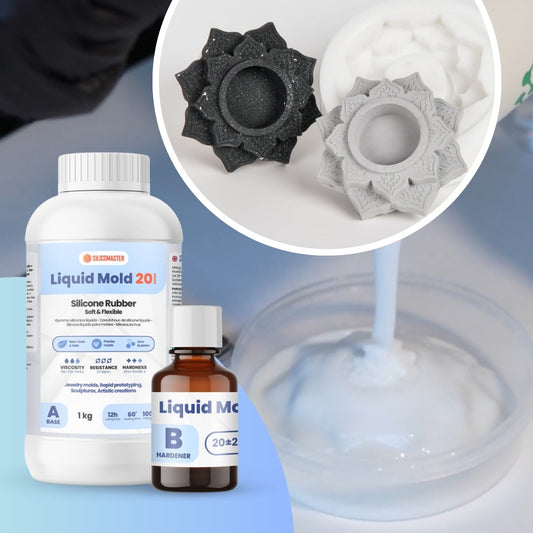

Tin-Cured Silicone – Liquid Mold

Tin-cured silicones, such as Liquid Mold, are less durable in the long term but represent an economical option for projects where longevity is not a priority.

Examples of use: Single-use or short-term projects such as artistic models, event sculptures, or small decorative productions.

2. Precision and Material Shrinkage

Platinum-Cured Silicone – Pure Mold

This type of silicone has superior shape retention and a very low shrinkage rate, making it ideal for moulds where precision is essential. Pure Mold is perfect for complex shapes and gear replicas, ensuring the final dimensions of the reproduced object remain constant.

Examples of use: Jewellery making, miniatures, or composite components, where even small variations in shape or size could compromise the final result.

Tin-Cured Silicone – Liquid Mold

Tin-cured silicones may experience slight shrinkage after curing, making them less suitable for precision applications. However, they are highly effective for artistic models or prototypes where minor dimensional variation is acceptable.

Examples of use: Moulds for sculptures, decorations, and objects where exact reproduction of the original is not critical.

3. Flexibility and Repeated Use Resistance

Platinum-Cured Silicone – Pure Mold

Platinum-based silicones are known for maintaining flexibility and strength even after repeated use. This makes them ideal for moulds that are regularly deformed during production, such as in series production or in the creation of complex artistic pieces.

Examples of use: Moulds for industrial prototyping or decorative items used multiple times.

Tin-Cured Silicone – Liquid Mold

Less flexible and durable than their platinum counterparts, tin-based silicones are more prone to losing elasticity with frequent use. They are better suited for projects with a limited number of cycles.

Examples of use: Simple or short-term projects such as small decorative objects.

Selection Guide: How to Choose the Right Silicone

-

For high-frequency use projects: Platinum-based silicones like Pure Mold are ideal thanks to their durability, resistance, and ability to be reused often.

-

For larger projects or cost-efficiency: Tin-based silicones like Liquid Mold offer an excellent solution for artistic creations, single-use models, and moulds not intended for food contact or very long-term use.

© All rights reserved. Any reproduction, distribution or unauthorised use of the content on this site is prohibited without written consent from the copyright holder.

RESINPRO SASU, 4 Allée du Marais de Condé, Rochy-Condé, 60510, France

VAT FR05842797722, SIRET 842 797 722 00019