Even professionals can make mistakes when creating silicone moulds. In this section, we analyse some of the most common errors and provide practical solutions to avoid them, improving the quality and durability of SILICOMASTER by ResinPro® moulds.

1. Formation of Air Bubbles in the Silicone

Mistake: During casting, air bubbles can form in the silicone, especially in models with intricate details. Air bubbles compromise the precision of the mould and may weaken it.

How to Avoid It:

-

Mix the components carefully to avoid incorporating too much air.

-

Degas the Silicone: Before casting, use a vacuum chamber to eliminate trapped air.

-

Slow, Targeted Pouring: Pour the silicone slowly, preferably from one corner of the model, so it flows naturally and reaches all the fine details.

2. Poor Adhesion to the Model Details

Mistake: The silicone does not distribute evenly, resulting in lost details or empty areas in the mould.

How to Avoid It:

-

Clean the Model: Make sure the model is free of dust or oils, which can interfere with silicone adhesion.

-

Pre-coating the Model: The day before the main casting, brush the model with the same silicone you will use for the mould; this will prevent small undercuts from trapping air bubbles.

3. Demoulding Too Early

Mistake: Removing the mould too early may cause deformation or damage.

How to Avoid It:

-

Respect the Curing Times: Follow the curing times indicated for each product. Pure Mold has different timings compared to Liquid Mold, so be sure to follow the product instructions.

-

Stable Ambient Temperature: Avoid working in environments that are too cold or hot, as temperature affects curing times.

4. Shrinkage or Mould Deformation

Mistake: Moulds may undergo slight shrinkage or deformation. For projects requiring high precision, use Pure Mold platinum-based silicone, which ensures virtually no linear shrinkage.

How to Avoid It:

-

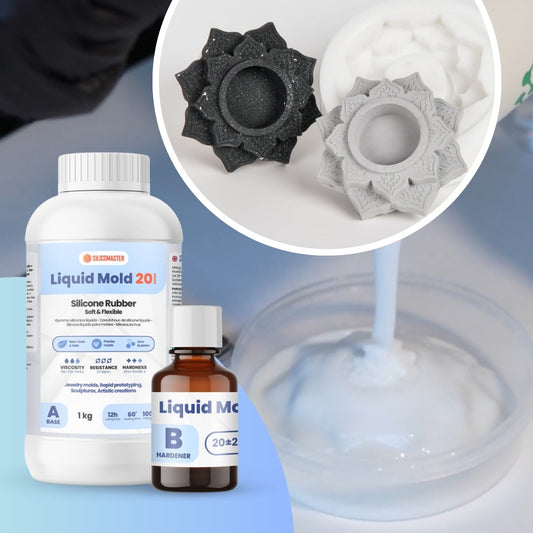

Choose the Right Silicone: If dimensional stability is essential, use Pure Mold (addition-cured) with almost zero shrinkage (< 0.05%). Liquid Mold may shrink slightly more (up to 1.5%).

-

Use a Rigid Mother Mould: For large or complex moulds, use a rigid support mould made of plaster or resin to help maintain the shape during curing.

5. Fragile or Tear-Prone Mould

Mistake: A mould that is too thin or made with unsuitable silicone may tear easily.

How to Avoid It:

-

Adjust Mould Thickness: Ensure a minimum thickness of at least 5 mm for structural strength.

-

Use Tear-Resistant Rubber: For demanding projects, choose high-tear-resistance versions like Pure Mold or the Liquid Mold HR series.

6. Improper Silicone Curing

Mistake: Incorrect mixing of components may lead to incomplete curing and a soft, unusable mould.

How to Avoid It:

-

Correct Mixing Ratio: Strictly follow the specified ratio (1:1 for Pure Mold, 100:5 for Liquid Mold – BY WEIGHT). Weigh each part separately and precisely before mixing.

-

Accurate Mixing: Mix slowly but thoroughly, scraping the sides and bottom of the container to ensure full incorporation of both components.

7. Difficult Model Removal

Mistake: Removing the model may be difficult, damaging either the mould or the model.

How to Avoid It:

-

Use a Release Agent: Apply a release agent to the model before casting to ease demoulding.

-

Choose the Right Hardness: For detailed models or undercuts, select softer Shore silicone that is better suited for “glove” or “sock” demoulding techniques.

8. Improper Mould Storage

Mistake: Storing moulds in unsuitable conditions may lead to yellowing or loss of elasticity.

How to Avoid It:

-

Clean and Dry: Always wash and dry the mould before storing it.

-

Store in a Cool, Dry Place: Avoid direct sunlight and store in a cool environment. A light dusting of talcum powder can help maintain the silicone’s elasticity.

By following these tips, you can avoid the most common mistakes and achieve professional and long-lasting results with SILICOMASTER by ResinPro® silicones.

© All rights reserved. Reproduction, distribution or unauthorised use of the content on this site is prohibited without the written consent of the copyright holder.

RESINPRO SASU, 4 Allée du Marais de Condé, Rochy-Condé, 60510, France

VAT: FR05842797722 — SIRET: 842 797 722 00019