Project Examples and Case Studies

To showcase the versatility and quality of SILICOMASTER by ResinPro® silicones, we present some practical project examples and case studies that demonstrate how the various products can be used effectively in different industries. These examples also provide helpful tips for achieving excellent results and maximising the use of silicone.

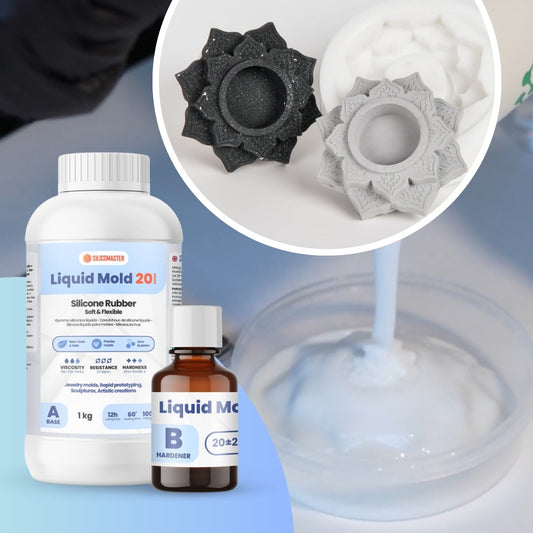

Project 1: Silicone Jewellery Creation – Liquid Mold

Description: A craft workshop specialising in the production of unique jewellery chose Liquid Mold (tin-cured) from SILICOMASTER by ResinPro® to create detailed and precise moulds. The Shore A 20 hardness proved perfect for producing small details, allowing smooth and flawless surfaces.

Process: The workshop prepared detailed moulds for rings and pendants. To avoid air bubbles, a vacuum chamber was used before pouring.

Result: The resulting jewellery had sharp details and smooth surfaces, and the mould was reused several times without deterioration.

Project 2: Decorative Brick Moulds – Liquid Mold

Description: A construction company chose Liquid Mold with Shore A 40 to create moulds for decorative bricks and architectural elements for both indoor and outdoor use. The strength and hardness of the silicone ensure long durability, even with the weight of concrete.

Process: The silicone was poured over a decorative brick model and left to cure for the recommended time. A release spray was applied to facilitate the removal of the concrete.

Result: The moulds produced dozens of bricks without losing detail or deforming, demonstrating the high mechanical resistance of Liquid Mold.

Project 3: Precision Mechanical Prototyping – Pure Mold

Description: An engineering firm used Pure Mold (platinum-cured) to create high-precision moulds for mechanical components. The low shrinkage of the silicone and Shore A 50 hardness allowed minute details to be accurately replicated.

Process: Silicone was poured into moulds for mechanical parts, keeping the model under pressure to prevent air bubbles. After curing, the mould maintained its shape and allowed for easy prototype removal.

Result: The resulting prototypes maintained millimetre-level precision, making Pure Mold ideal for applications requiring dimensional stability.

Project 4: Cinematic Prosthetics – Shore A 0–10

Description: A team of special effects makeup artists used SILICOMASTER by ResinPro® silicone with Shore A 0–10 to create realistic facial prosthetics and masks for a science fiction film. This extremely soft and flexible silicone allows for natural movement of prosthetics applied to actors.

Process: After sculpting the prosthetics, the silicone was poured and left to cure. Flesh-toned pigments were added for a realistic appearance.

Result: The prosthetics looked incredibly lifelike, with natural textures and movement that closely mimicked human skin. The team reported excellent durability, even after hours of use under hot studio lights.

Project 5: Moulds for Sweets and Chocolate – Silfood

Description: A patisserie selected Silfood to create moulds for chocolates and decorative sweets. As a food-safe certified silicone, Silfood offers safety and practicality for moulds in direct contact with food.

Process: The workshop poured silicone over a decorative chocolate model, using a release spray. Once cured, the mould was washed and prepared for food production.

Result: The sweets produced using Silfood moulds had sharp detail and were easily demoulded without damage. The workshop found Silfood ideal for producing high-quality edible products.

© All rights reserved. Reproduction, distribution, or unauthorised use of the contents on this site is prohibited without the written consent of the copyright holder.

RESINPRO SASU, 4 Allée du Marais de Condé, Rochy-Condé, 60510, France

VAT FR05842797722, SIRET 842 797 722 00019