The creation of silicone moulds is a versatile technique that, when done properly, allows for cost-effective, durable, and highly detailed results. In this chapter, we explore practical techniques and tips to optimise the use of SILICOMASTER by ResinPro® silicones and maximise mould quality.

1. Choosing the Right Silicone

-

For high-precision and long-lasting projects: Use Pure Mold (platinum-based), which offers superior dimensional stability, minimal shrinkage (< 0.05%), and high wear resistance.

-

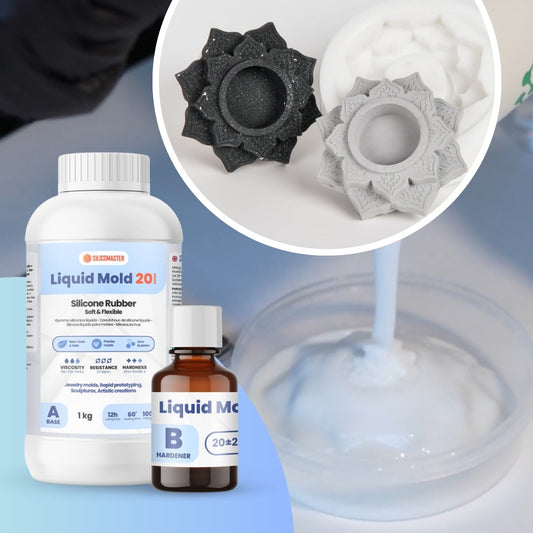

For cost-effective, high-volume projects: Liquid Mold (tin-based) is a more budget-friendly option, ideal where price-performance ratio is important. Ensure the correct catalyst ratio (100:5) for best results.

2. Optimising Curing Time

-

Using the Catalyst: Weigh the catalyst separately before mixing with the silicone – a precise ratio ensures perfect curing.

Some tin-based silicones allow for slight variations in the silicone/catalyst ratio to adjust the curing speed. -

Working in Controlled Temperatures: Keep the room between 20–25 °C for stable and even curing. Warmer temperatures accelerate curing time.

3. Reducing Costs with Support Moulds

-

Economical Support Moulds: For large silicone moulds, consider building a mother mould using plaster or resin. This provides structural support while reducing silicone consumption and improving durability.

-

‘Sock’ Demoulding Technique: For models with few undercuts, low Shore hardness silicone can be removed by simply pulling off the mould, eliminating the need for a support mould.

4. Preventing Air Bubbles for Better Quality

-

Degassing the Silicone: Use a vacuum chamber to degas the silicone before pouring to eliminate air bubbles.

-

Slow, Controlled Pouring: Pour slowly and from one point to let the silicone flow evenly and reach all fine details of the model.

5. Enhancing Detail with Pigments and Additives

-

Using Pigments: Add pigments to the silicone to create coloured moulds, which can help with visual control during use.

-

Thixotropic Additives: For brush-on applications on vertical surfaces or complex details, use 1.5–2% thixotropic agent to increase viscosity, reducing drips and ensuring better control.

6. Easy Demoulding for Longer Mould Life

-

Use Release Agents for Rigid Moulds: For higher hardness moulds, a release agent helps preserve detail and extend mould life.

-

Cool Before Demoulding: If the material heats up during curing, wait until the mould is fully cooled before removal to avoid deformation.

7. Maintaining Moulds in Good Condition

-

Regular Cleaning: Wash moulds with warm water and mild soap after each use, avoiding abrasive substances that could damage the surface.

-

Proper Storage: Store moulds in a dry place away from direct sunlight. Occasionally dusting with talc helps maintain silicone elasticity.

-

Repairing Minor Damage: For small tears or wear, apply a thin layer of fresh silicone to repair and extend the mould’s lifespan.

© All rights reserved. Reproduction, distribution, or unauthorised use of the contents on this site is prohibited without written consent of the copyright holder.

RESINPRO SASU, n° 4 Allée du Marais de Condé, Rochy-Condé, 60510, France – VAT FR05842797722, SIRET 842 797 722 00019