What Is Mould-Making Silicone?

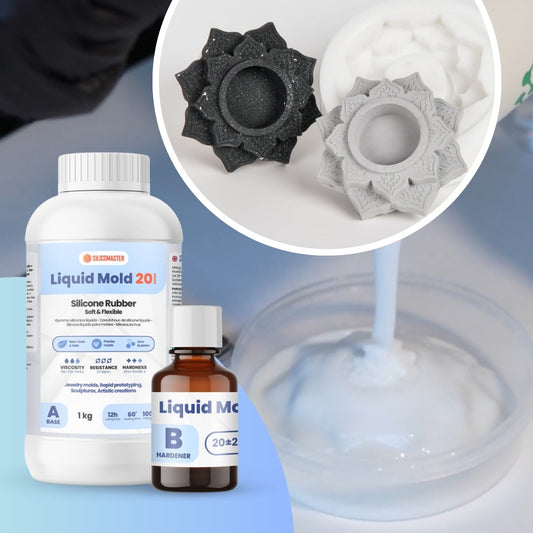

Definition: Mould-making silicone is a two-part material (Part A + catalyst B) that mixes and cures in just a few hours, forming a flexible and durable rubber.

It is used to reproduce 3D objects in resin, soap, wax, concrete, and much more.

How Do You Measure and Mix Silicone?

It depends on the type: condensation or addition cure.

-

Most are mixed in a 100:5 or 100:10 weight ratio

-

Use a digital scale for maximum accuracy

-

Mix gently but thoroughly for at least 2–3 minutes, scraping the sides and bottom of the container

💡 Pro Tip: If the catalyst is coloured, check that the final colour is even and streak-free.

Can You Speed Up Silicone Curing?

Yes, with heat:

-

At 20°C, curing takes between 4 and 24 hours

-

At 30–40°C, it can be halved or reduced even further

❗ Caution: Avoid overheating if using plastic moulds or very detailed models — they could warp or deform.

What Is Silicone Cure Inhibition?

This happens when silicone fails to cure due to contact with certain materials:

-

Latex

-

Sulphur-based clays

-

Some semi-cured plastics

🛠️ Solution: Apply a protective coating or varnish before pouring, or run a small-scale test.

What Materials Can Be Used as Models for Moulds?

Almost anything:

-

Plastic toys

-

Ceramic figures

-

3D printed models (with fully cured resin)

-

Flowers, fruits, tools, etc.

📌 Important: If the object is porous (e.g. plaster, wood), apply a release agent to prevent silicone absorption.

How to Avoid Air Bubbles in Silicone

-

Mix slowly to minimise air inclusion

-

Pour from a height (a thin stream helps break bubbles)

-

Use a vacuum chamber after mixing if available

-

Tap the container or mould gently

-

A gentle vibration (e.g. washing machine, vibrating tray) also helps

Which Silicone Type Suits Each Application?

| Project Type | Recommended Silicone |

|---|---|

| Resin moulds | Addition-cure (platinum) silicone |

| Soap moulds | Condensation-cure silicone |

| Large moulds | Fluid silicone |

| Very detailed moulds | Low-viscosity silicone |

| Mechanical parts | Tear-resistant silicone |

Can You Colour Silicone?

Yes! Use specific silicone pigments, added to Part A before mixing with the catalyst.

⚠️ Do not use water-based or acrylic pigments — they may inhibit curing.

How to Store Leftover Silicone

-

Store in a cool, dry place, away from sunlight

-

Seal containers tightly

-

Avoid cross-contamination (don’t mix up lids)

-

Shelf life: 6–12 months after opening

Safety Precautions

-

Wear gloves and protective goggles

-

Work in a well-ventilated area

-

Avoid inhaling fumes if using heat

-

Keep out of reach of children and pets

✅ Summary: The Three Golden Rules for Using Silicone

-

Measure accurately and mix carefully

-

Avoid inhibition (watch out for contaminated surfaces)

-

Control the environment (temperature and bubbles)