In the world of resin, there are details that may seem minor at first glance but make a significant difference in the final outcome.

One such detail — often underestimated — is the transparency of the silicone mould.

Have you ever used a resin mould, invested time, care, and materials… only to find, upon demoulding, an air bubble or flaw that ruins the entire piece?

In many cases, the problem isn’t with the resin or your technique — it’s simply that you couldn’t see what was happening inside the mould during the curing process.

Benefits of Translucent Moulds for Resin: Why Choose Them

One of the main advantages of translucent silicone moulds is that they allow continuous visual control during curing.

This means you can intervene in real time to fix bubbles or areas where the resin isn’t distributing properly.

Many makers ask: Why use translucent moulds with epoxy resin?

The answer is simple: you avoid having to redo a piece due to a mistake that could have been prevented.

How to Avoid Air Bubbles in Resin Moulds with Pure Mold

Air bubbles are one of the most common and frustrating issues when working with resin.

With opaque moulds, you often won’t notice the bubbles until it’s too late.

With translucent moulds like Pure Mold, spotting bubbles is easy: you can see them forming in real time and move or adjust the mould before the resin sets.

Best Moulds for Rotocasting with Resin: A Choice That Makes a Difference

Rotocasting requires an even distribution of resin along the inner walls of the mould.

Using translucent moulds lets you observe how the resin behaves during the process, allowing you to adjust your movements, dosage, or angles to avoid errors.

Guide to Choosing Silicone Moulds for Epoxy Resin: Key Factors

If you’re looking to buy new moulds for your projects, consider the following points:

-

Prioritise translucency if you need precision and control

-

Think about the type of project: for inclusions or fine details, translucent moulds are ideal

-

Assess silicone quality: Pure Mold offers durability, flexibility, and clarity

-

Choose the shape and size based on the design you want to achieve

👉 A well-chosen mould improves both the final result and the crafting experience.

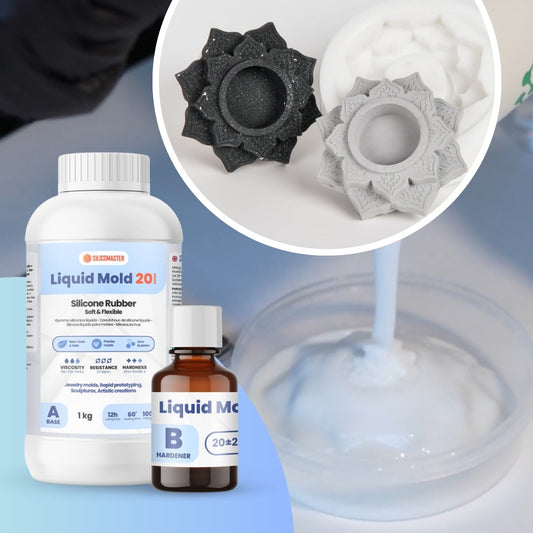

Pure Mold 10 - Silicone for Crafts and Fine Details

Pure Mold 20 - Universal Silicone for Sculptures and Artistic Objects

Pure Mold 30 - Ideal Silicone for Moulds in Concrete, Plaster, Mortar, and Decorative Stones

Conclusion: Transparency That Transforms Your Resin Work

Ultimately, the translucency of a silicone mould gives you an invaluable advantage:

real-time control.

It’s the difference between hoping everything went well and knowing exactly what’s happening at every stage.

If you're aiming for professional results, fewer mistakes, and more satisfaction, choose moulds that let you see more.

It’s not just about looks – it’s a precision tool.

💡 Pure Mold: your trusted ally when results matter, when every detail counts, and what you see... is exactly what you meant to create.